4 Decades of Experience in Commercial & Residential Roofing

Our team takes pride in our work and the quality of materials we use. This company still considers a handshake a bond of our commitment to building and repairing your roof right….the FIRST time.

So if your business needs a new flat TPO roof system, your current TPO roof needs repairing, or you have recently suffered some storm damage, give us a call at 832-671-1357 or fill out the information below, and we will provide you FREE quote immediately!

How We Can Help

Commercial TPO Roofs

Industrial TPO Roofs

Retrofit TPO Roofs

TPO Roof Repairs

TPO Roof Maintenance

How We Can Help

Commercial TPO Roofs

Industrial TPO Roofs

Retrofit TPO Roofs

TPO Roof Repairs

Definitions

TPO Roofing Overview

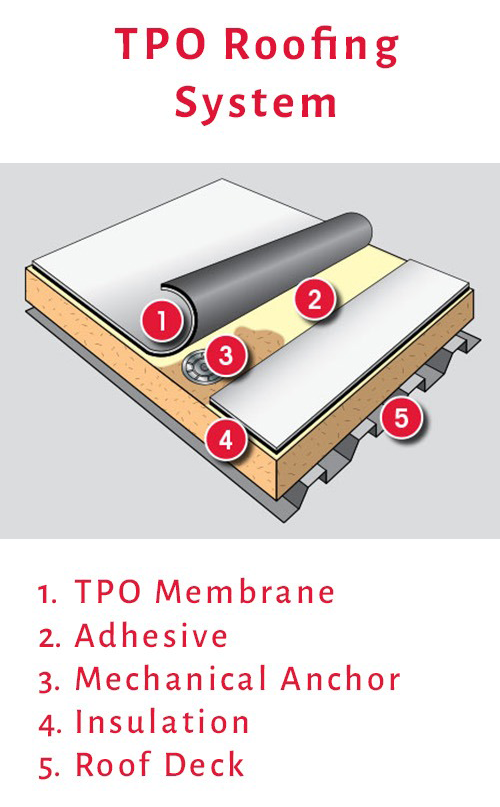

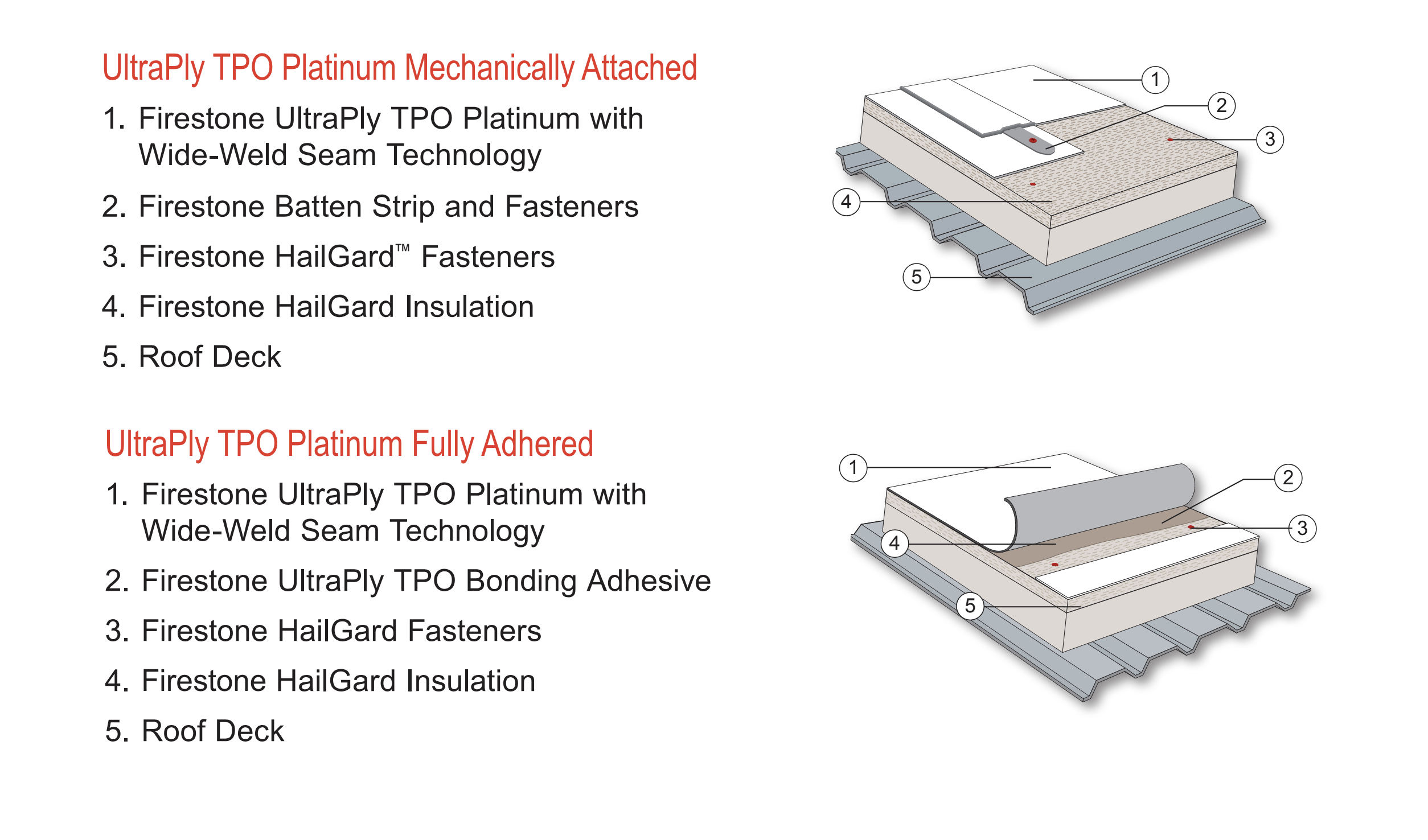

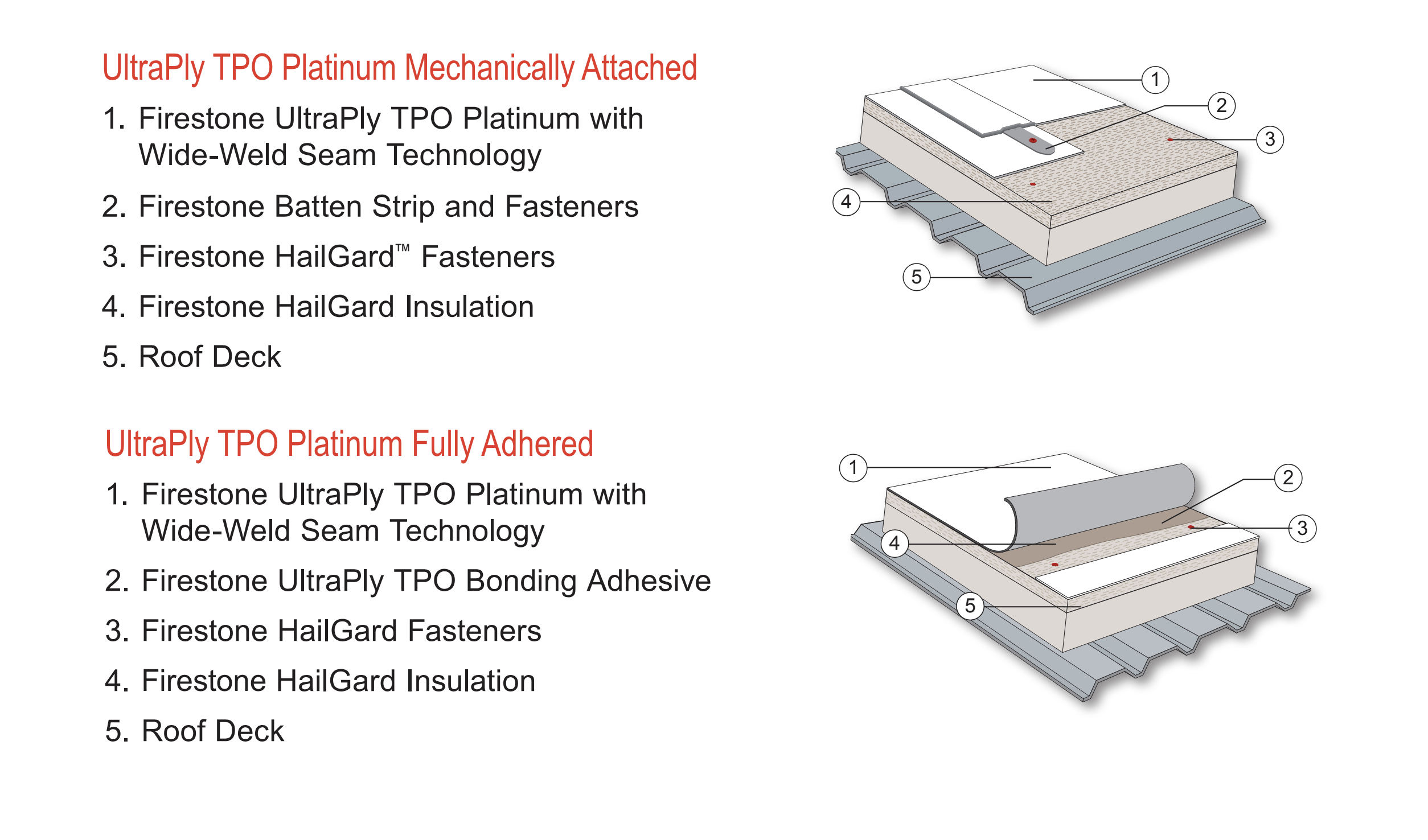

Thermoplastic Olefin (TPO) roofs are a popular choice for flat or low-slope roofing applications. Known for their durability, energy efficiency, and straightforward installation process, TPO membranes offer a reliable solution for commercial and industrial buildings. Below is a breakdown of the components in a typical TPO roofing system:

1. Membrane: The primary waterproofing layer, made of a single-ply thermoplastic material.

2. Insulation: Provides thermal resistance, helping to maintain comfortable building temperatures.

3. Cover Board: A rigid layer that protects the insulation and enhances the roof’s durability.

4. Roof Deck: The structural foundation, usually constructed from plywood or metal.

5. Flashing: Metal strips installed around penetrations, edges, and corners to prevent water infiltration.

6. Edge Detail: A termination bar or metal edge that secures the TPO membrane along the roof’s perimeter.

7. Roof Membrane Adhesive: An adhesive used to bond the membrane to the insulation or cover board.

8. Roofing Screws and Plates: Fasteners that secure the TPO membrane to the roof deck.

9. Roof Drain: A system that facilitates water drainage from the roof, directing it away from the building.

10. Roof Curb: A raised platform that supports rooftop equipment, such as HVAC units or skylights.

TPO roofing is not only cost-effective but also environmentally friendly, with its white reflective surface helping to lower energy costs by reflecting heat and UV rays. This makes it a favored option for green building initiatives.

Contact us today for more information!

About TPO Roofing

Flat roof structures, short for Thermoplastic Polyolefin, are a modern roofing solution admired for their durability and versatility.

Accordingly, a roof system encompasses a single-ply roofing membrane, ingeniously reinforced by a securely installed solid substrate, which frequently takes the form of an engineered insulation system.

Typically employed on flat or low-sloping roofs, this roofing offers a comprehensive solution for diverse architectural needs. One notable aspect of TPO roofing lies in its flexibility, allowing it to easily adapt to various installation requirements and building designs. The TPO roof membrane, available in a range of thicknesses, commonly spans from 40-mil to 80-mils or even thicker, catering to specific project demands and environmental factors. This variability in thickness ensures that TPO roofs can effectively withstand the rigors of different climates and provide long-lasting protection against the elements. Additionally, the composition of TPO membranes often includes advanced additives and reinforcements, enhancing their resistance to UV radiation, punctures, and other external stresses.

Unquestionably, TPO roofing emerges as a comprehensive solution, offering both structural integrity and aesthetic appeal for a wide array of commercial and industrial applications.

Definitions

TPO Roofing Overview

Thermoplastic Olefin (TPO) roofs are a popular choice for flat or low-slope roofing applications. Known for their durability, energy efficiency, and straightforward installation process, TPO membranes offer a reliable solution for commercial and industrial buildings. Below is a breakdown of the components in a typical TPO roofing system:

1. Membrane: The primary waterproofing layer, made of a single-ply thermoplastic material.

2. Insulation: Provides thermal resistance, helping to maintain comfortable building temperatures.

3. Cover Board: A rigid layer that protects the insulation and enhances the roof’s durability.

4. Roof Deck: The structural foundation, usually constructed from plywood or metal.

5. Flashing: Metal strips installed around penetrations, edges, and corners to prevent water infiltration.

6. Edge Detail: A termination bar or metal edge that secures the TPO membrane along the roof’s perimeter.

7. Roof Membrane Adhesive: An adhesive used to bond the membrane to the insulation or cover board.

8. Roofing Screws and Plates: Fasteners that secure the TPO membrane to the roof deck.

9. Roof Drain: A system that facilitates water drainage from the roof, directing it away from the building.

10. Roof Curb: A raised platform that supports rooftop equipment, such as HVAC units or skylights.

TPO roofing is not only cost-effective but also environmentally friendly, with its white reflective surface helping to lower energy costs by reflecting heat and UV rays. This makes it a favored option for green building initiatives.

Contact us today for more information!

ABOUT TPO

While flat roof structures, short for Thermoplastic Polyolefin, represent a modern roofing solution admired for its durability and versatility.

Accordingly a roof system encompasses a single-ply roofing membrane, ingeniously reinforced by a securely installed solid substrate, which frequently takes the form of an engineered insulation system.

Typically employed on flat or low-sloping roofs, this roofing offers a comprehensive solution for diverse architectural needs. One notable aspect of TPO roofing lies in its flexibility, allowing it to adapt to various installation requirements and building designs with ease. The TPO roof membrane, available in a range of thicknesses, commonly spans from 40-mil to 80-mils or even thicker, catering to specific project demands and environmental factors. This variability in thickness ensures that TPO roofs can effectively withstand the rigors of different climates and provide long-lasting protection against the elements. Additionally, the composition of TPO membranes often includes advanced additives and reinforcements, enhancing their resistance to UV radiation, punctures, and other external stresses.

Unquestionably TPO roofing emerges as a comprehensive solution, ffering both structural integrity and aesthetic appeal for a wide array of commercial and industrial applications.